Apex Japan Co., Ltd has unique developed to produce exclusive-technological “APEX™” Polycarbonate resins under our original compounding process systems which have been consumed as plastics molding raw materials by electric home appliance makers, automobile parts makers, home appliance makers and stationary makers in overseas and domestic markets.

| PC Grades | |

| General purpose grade (compounding & injection) |

LB LMB MB |

| Extrusion grade | HMB |

| High flow grade |

SLB M17R |

|

Flame retardant grades UL94 V-0(2.5mm) V-2(1.5mm) |

FR |

| Standard black grade |

LB-BLACK |

| Anti static grade |

LBSE-BLACK |

| Anti abrasion grade |

AF0010N AF0003N |

| Glass Fiber reinforced grade | LMG-G10 |

| Surface Hardness grade *Pencil hardness: F-H | LB-H New Click |

| Taber Resistaant grade (Less scratch haze) | PC82R New |

| Post-consumer grade (Natural clear color) | POST - 1 , 2 , 3 |

| Application |

|

|

Automobile parts, House appliance, Electric home appliance, Household utensil goods, Daily utensil goods, Stationary goods and Office equipment etc.,

APEX resins have been used for the axis of ball point pens, mechanical pencil and nameplates and clips etc., which goods are approved to use ECOMARK.

|

|

Company brochure (Japanese) New

【SDS】

Material Safety Data Sheet(MSDS) for APEX™ general purpose grades

Material Safety Data Sheet(MSDS) for APEX™ Flame Retardant FR grades

【TDS】

High hardness resistant grade(LB-H) New

Taber Resistaant grade (PC82R) New

Post-consumer grade(Natural clear-POST-1,2,3)

.jpg)

PC/PET alloy resins “PETCARBO® have been unique developed exclusive-technological producing under our original compounding process system which alloyed resins have the excellent function such as the weather resistance, the chemicals resistance and the mechanical properties.There has been the quite difficult for the conventional plastics resins to get such an excellent function by our “PETCARBO®”.

| PC/PET Grades | |

| General purpose grades | AJ-I-071H AJ-I-071ER AJ-I-071M |

| Heat resistance grade | AJ-IH-771 |

| High flow grades | AJ-HF-910 AJ-HF-920 AJ-HF-930 |

| Sheet extrusion grades | AJ-EX-772 AJ-EX-710 |

| Flame retardant grades | AJ-FR-905 AJ-FR-906 |

| Transparent general purpose grade | CL-1140 |

| Transparent Flame retardant grade | FR-1141 |

| Glass Fiber reinforced grade | IH771G10 |

| Glass Fiber reinforced flame retardant grade | FR1003G10 |

| Characteristics | |

|

These kinds of resins have the excellent chemicals resistance, the excellent weather resistance and have the mechanical strength more than twice of that of ABS resin. Further more these kinds of resins can get approval to obtain [ECOMARK] because of compounded with recycled resins and are quite gentle to the environment.

|

|

| Application | |

|

Household products, Exterior appliances, Electrical appliances, Amusement products such as Carry Bags, Automobile parts, IC cards, Amusement parts etc.,

|

|

【TDS】

We have developed Polyester Copolymer - injection, extruson and high heat grades.

Transparent, high-impact strength, scratch resistance, Chemical resistance and high heat resistance(X02 grade).

| Co-polyester Grades | |

| Injection - General purpose | X01 |

| Extrusion - General purpose | X00 |

| Heat resistance grade | X02 |

| Characteristics | |

|

These kinds of resins have following characateristics: - Transparent Clear - Good impact strength similar to Polycarbonate - Good heat Resistance (High Heat Grade X02 : 101℃ (213℉)) - Good chemical resistance (Resistant to Alkalinity, Oil, Alcohol and etc.) - Scratch Resistance

Applications for PC and transparent ABS can replace with PEPLORENE™. |

|

| Application | |

|

Application: Stationary items(transparent + impact strength), sagety goggles(transparent + chemical resistance + impact strength), office mat(scratch resistance), name tag (extrusion + transparent + chemical resisntance + impact strength), electrical appliance parts (transparent to go any color + chemical resistance + impact strength) and etc

|

|

【TDS】

Amber transparent, good mechanical properties, high heat resistance(HDT >174℃), hydrolysis resitance(cold and hot water) and chemical resitance. For parts which needs high heat resistance

and hydrolysis resitance such as microwave, kitchen and bath electrical appliance, plumbing manifold

hot water compatible fitting and etc.

| PSU Grade | |

| General purpose grade | Natural recycle grade |

| Characteristics | |

|

Transparent Good mechanical properties High heat resistance Chemical resistance Hydrolysis resistance(cold and hot water) Recycle grade |

|

| Application | |

|

Home electrical appliance Bath Shower parts・Kitchen・House (water pipe)・and etc

Microwave Coffee maker parts connector Switch parts plumbing manifold Shower parts Pump Automobile (Dynamo、fuse、battery cap、sensor and etc )

|

|

【TDS】

Excellent mechanical properties, wear resistance, electrical insulation, radiation resistance, high heat resistance(Continious use >260℃(480℉)), hydrolysis resitance(hot water) and chemical resitance. Recycled from one grade film/parts. Gear parts which need wear resistance and valve parts/high-voltage terminal which need hydrosis resistance and electrical insulation.

| PEEK Grade | |

| General purpose grade | Natural recycle grade |

| Characteristics | |

|

Super high heat resistance High mechanical properties Chemical resistance Hydrolysis resistance Electrical insulation Radiation resistance Recycle grade |

|

| Application | |

|

Gear・Bearing・Screw、Valve parts for gas and oil, Semiconductor manifacturing equipment parst (carrier case and etc) Presicion machines High-voltage terminal Metal alternatives Heat resistant tape etc |

|

【TDS】

【Molding Condition】

Biomass Plastic is made of starch resin and can be compouded/blend with thermoplastic resins such as HDPE, LLDPE, LDPE, PP, PC, ABS and etc. Biomass plastics help to reduce both fuel based plastic and green gas house generation. Application would be injection, extrusion suc as film/sheet for agricultural materials and packages.

| Grade | |

| Grade |

Biomass PC-Biomass PE-Biomass *Compound/blend with thermoplastic resins |

| Characteristics | |

|

Biomass Compound/blend with thermoplastic resins Recycleable |

|

| Application | |

|

Packing material・Package film・Agriculutural film・・Any parts need biomass material etc |

|

【Documents】

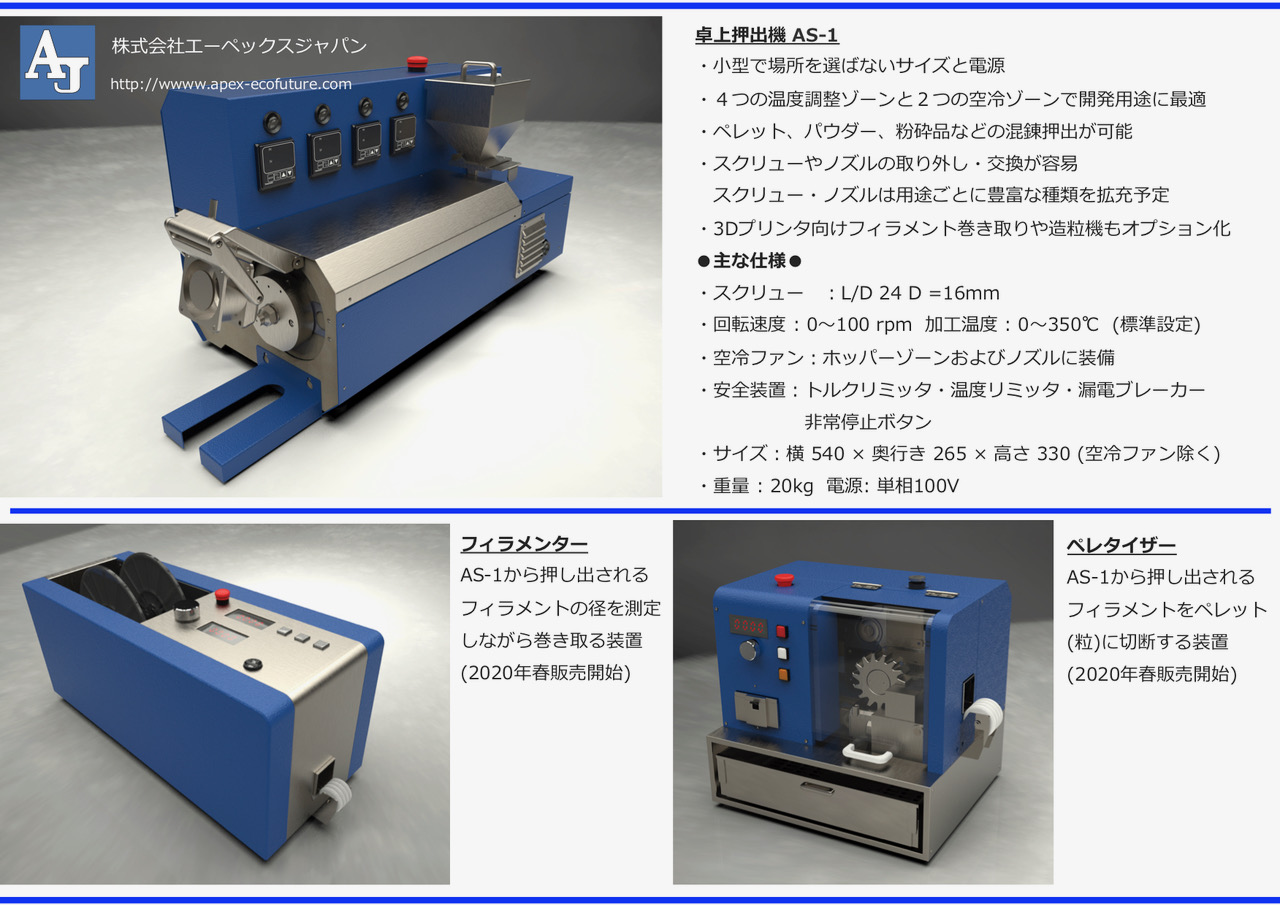

We have developed desktop single extruder AS-1 for lab test : compounding, 3D printer filament, fiber etc

As recycle manufacture and supplier, APEX JAPAN establihed recycle BRAND called MATATBI.

We have developed unique and stylish products for daily uses from the waste.